Work Round 4 - 08/16/2012

More work needs to be done to get this engine ready. Namely getting the flywheel back on and finalizing the harmonic balancer torque-down (160 ft-lbs!), installing the last head, torquing all head bolts, oil filter housing and filter, priming the system to verify it works properly, and doing the valve train install. I accomplished most of this tonight.

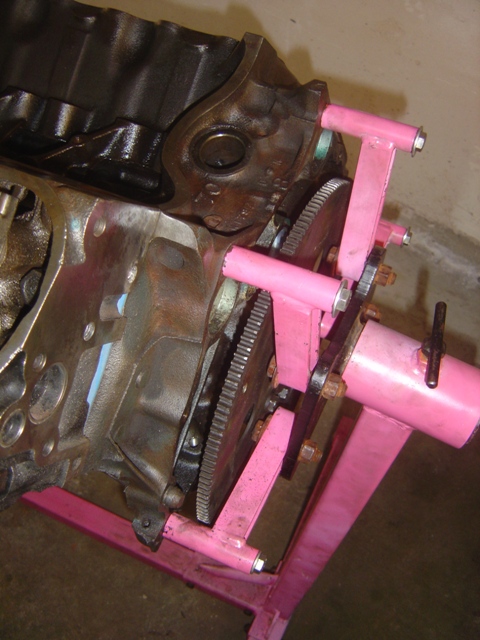

Flywheel is installed back on. Not too tricky or difficult, one bolt is missing though.

Head gasket is fit on after wiping the head and surface clean to ensure good contact.

70lbs of cylinder head is installed and both heads are torqued to 90 ft-lbs in steps of 30 ft-lbs (do all in the proper pattern to 30, then 60, then finally 90). This seems to give a much better and more uniform torque pattern to help ensure proper sealing of the engine. The engine stand now officially hates me. Fuel pump is also installed to officially and finally seal up the bottom end of the motor.

Oil filter housing is installed as is a new oil filter. Mechanical gauge is to be installed to verify oil pressure.

Loading 15W40 Delo oil into the engine. 6 full quarts! No leaks either so far, which is a good sign.

Oil pump will be primed with a drill that actually plugs in using a priming tool. The oil pump can easily drain a battery drill quickly, so corded is the way to go here.

Lifters were put in solely to get oil flow and pressure to the entire lifter gallery and top end. 60lbs of oil pressure was easy to get and the oil flowed quite nicely and it wasn't dirty or nasty either indicating that my cleaning was a good thing - it would shoot oil straight up almost 7 inches at the last lifter! Spun the crank around a few times to get good oil distribution along the lower end as well. Audrey was a super big help during all of this as she kept the drill spinning and the oil pressure up. Will re-apply break-in lube to the cam lobes and lifters when the push rods and lifters are finalized.

Valley pan goes back on to protect lifter valley from getting junk and trash in it.

Bagged up to keep everything out of the engine that is still open. Pulleys are handy for weight to keep plastic bag from blowing away. Need to get bigger trash can bags (55 gallon vs. the 35 I have).

Almost looks like a completed engine, doesn't it? Still nervous about the push rods and rocker arm geometry, we shall see when we go to install it all!

Return to 1971 Catalina

Last updated August 16th, 2012