The New Engine! - Part 3 - 02/18/2007

After such problems with the paint, it was time to bring out the big guns. Everyone on the web said to sand blast or hot tank the motor, but it was a runner. Why tear a perfectly good runner further apart than necessary? Steve found a tool that helped out...

The needle gun! Used in the Navy to strip paint from ANYTHING. The needles move back and forth. There is nothing you can do to yourself with this tool that can hurt you (except drop it on your foot) and it removes paint like mad.

The paint is coming off!

Even more progress!

More removal.

Even more removal. It's ready to paint now. What is left is scuffed up nicely to provide an amazing basecoat. This paint must have been some kind of marine grade epoxy applied with a brush. Whatever was done to this thing it is insanely tough. You couldn't chip it with a nail.

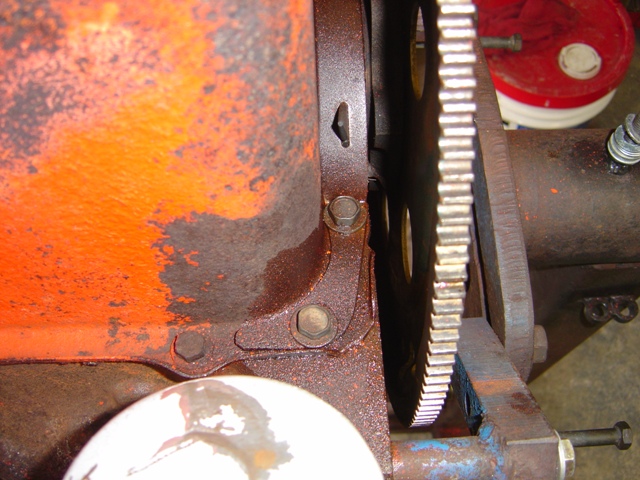

Time to remove the oil pan and put a new oil pump in it (cheap insurance). Note the factory braces are still in place.

Old oil pan. This engine is MAJORLY sludged up. Lots of back to back oil changes are in my future I see.

Old oil pump. Pickup screen is clogged with crap.

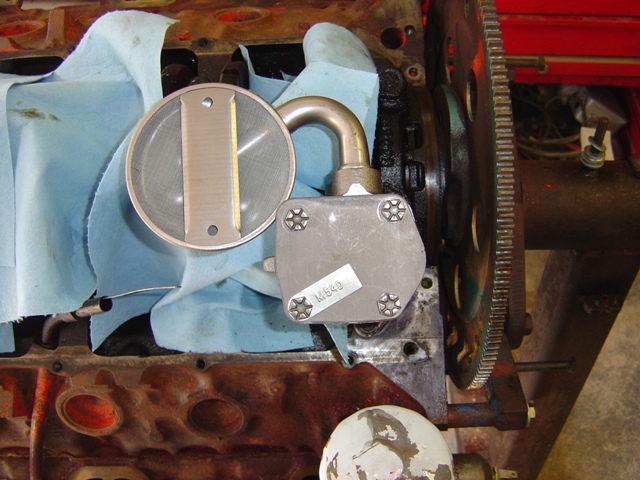

New 60lb oil pump is installed.

"New" pan installed. Of course as soon as I got this pan installed the bolt threads decided to give out on me. Le sigh. Sometimes you just can't win. Rather than buy a new pan we're going to see if we can't drill and tap a new bolt in. Right now we have a 5/8" 11 thread hole drilled and tapped. Then we realized we don't have a 5/8" 11 thread bolt. Le double sigh. If it leaks after we're done I'm just buying a new pan and be done with it.

Of course there are yet MORE problems. A hole in the timing cover. At least it was discovered BEFORE the engine was put together. All of these little things are reasons why engine building takes TIME.

Fixed the hole with some metal epoxy.

Nice. Let it cure for 24hrs naturally. Should do the trick. All of these little issues creep up, but at least we can deal with them. Nice to not have any deadlines.

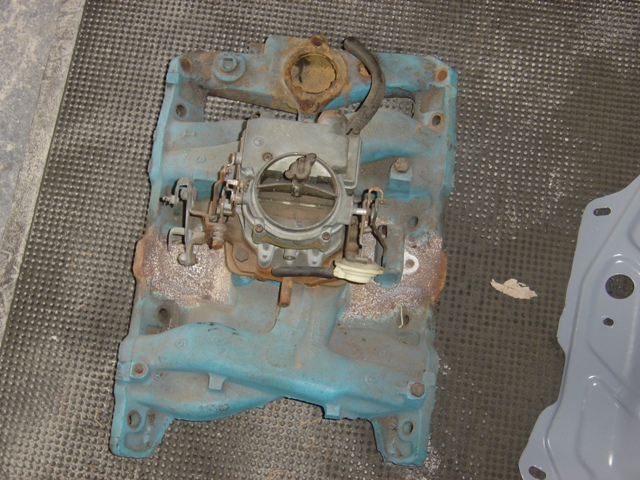

A swap meet special intake from 1971. Of course it has to be different than a '72, but at least it has no EGR. It will look right at home under the hood of the Lemans. My 2bbl collection really is starting to grow. I'll use one with an external hot air choke as the divorced choke setup has never been good to me. Converted to an electric choke for functionality, naturally!

After cleaning all of that, a thorough cleaning was done to the heads. The sludge was SO thick it came out in chunks. This engine was a good runner too (Steve tested it and it made no noises and had good oil pressure). It just goes to show that killing an engine really does take some time and neglect. Hopefully this engine will live a long and happy life of service.

Return to 1972 Lemans Page

Last updated February 18th, 2007