The New Engine! - Part 1 - 01/28/2007

The 455 in the car is on it's way out. It is tired and has a massive oil leak problem. This is not conducive to actually driving this car anywhere I want to go without worries. So I bought a 350 2bbl from Steve for $300. Sure, it's a 350 2bbl, but it has 6X-4 heads on it and those are worth $250-350 just because they are good heads for a 455 to get to a 9.5:1 CR, so it's not like it will be a waste. The 455 will be redone and put in the Trans Am!

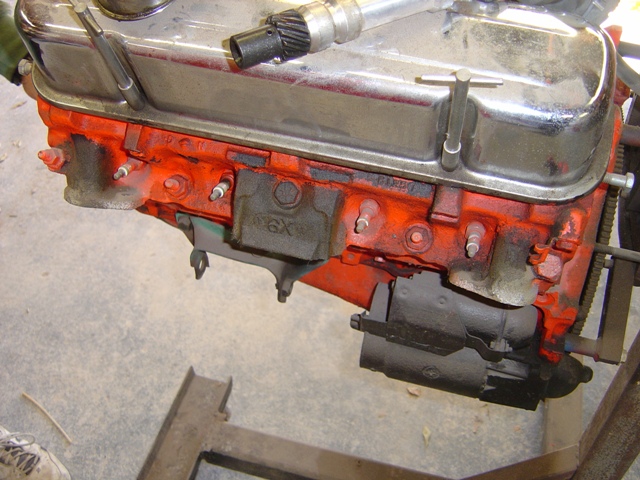

A 1975 350 2bbl I believe. From a non-AC car judging by the dipstick arrangement. Much nicer than the older version if you ask me. This piece will have to be removed and an AC one installed in it's place.

6X-4 heads. 8.0:1 on a 350. Good for the cat pee gas we have out here in California.

This is one complicated 2bbl setup. Several vacuum breaks and vacuum lines everywhere. Everything appears to be in decent shape, so it shouldn't be too much of a problem to get running again.

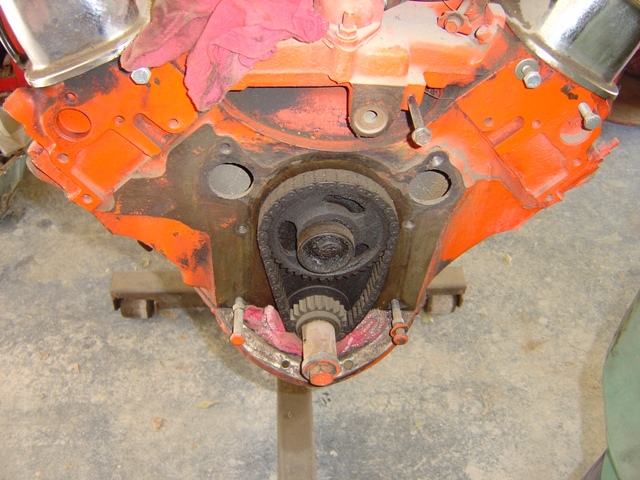

Timing chain. Some slop is present, so it will be replaced just because we are here already. Special rag magically keeps all contaminants out of environment, so I won't have to change the oil! Not.

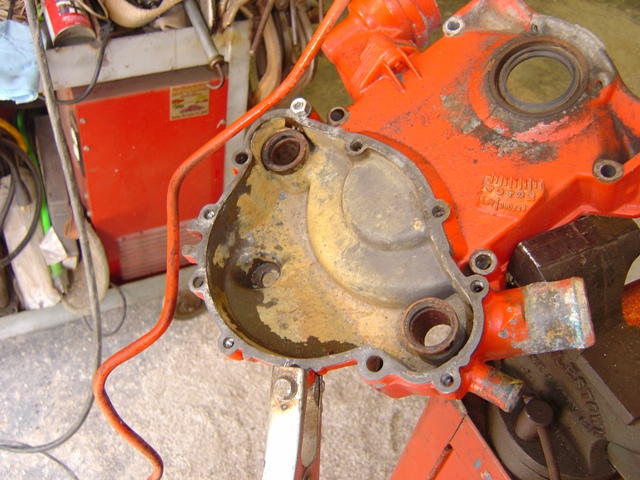

THE reason the motor was pulled. Three snapped off bolts in the timing cover.

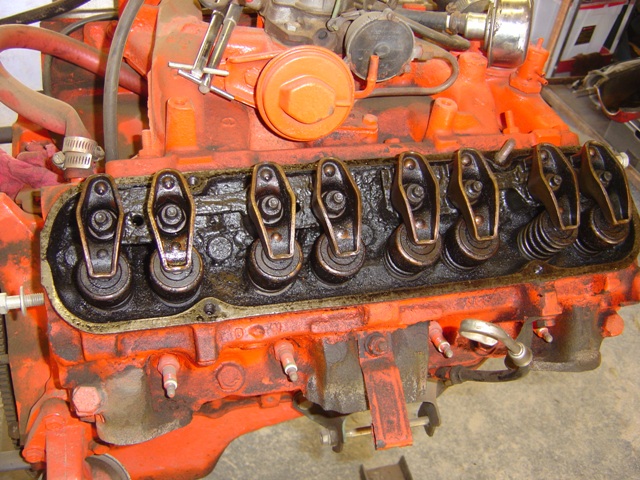

s00par d00par CHROME valve covers. Going to throw these away in place of stock valve covers (assuming the rockers will clear).

Still has the kick-up solenoid for the AC. This gives me a warm fuzzy so that I can install it properly and get it all working!

Stock rockers and valvetrain apparently, so no need for special super tall CHROME valve covers.

Kinda sludged up. Going to need to do several back to back oil changes in this beast once it is running.

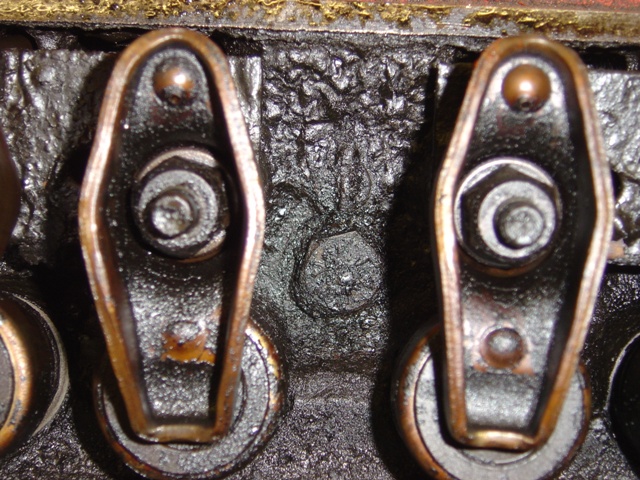

More sludge, but screw in studs! Bonus!

Unfortunately the bolts are not coming out with vise grips, so we need to get dirty.

Stick it in the vise and weld some bolts, 2 come out with little effort. One decides to be difficult.

Steve and Phil use a propane torch to heat up the bolt and timing cover (made of aluminum with steel bolts). Phil is on wrench duty and Steve handles torch and welding duties (need I say more?).

More heat. The bolt snapped off the stud about 15 seconds after this picture was taken (for the second time).

Drill it out! Right up the center! File it down a little bit, use a center punch and start drilling. We had to use 3 bits to get this thing out, our heating and beating had hardened the bolt...

And it is out!

I think a monkey put this engine together. They used teflon tape on the threads of the fuel line (BOTH ends). This goes to show how some people do NOT understand how the fittings work (it's a compression fitting, all the tape does is make a mess!).

This cover comes out nice and neat despite the problems with the 1 broken stud. A tap was used to clean up the threads, TONS of silicone came out of the bolt holes (more monkey handy work).

Fuel pump is seized. Notice how there is NO gasket in EITHER this picture or the previous one. That's right. The idiot who built this engine didn't use a gasket and just used silicone to put everything together. I have no idea if this engine ran for any length of time, it's sad to think about.

Yay. Making progress. Soon I will have a motor that runs and hopefully doesn't leak too much oil. And NO it will NOT be painted Chevy orange. Pontiac blue has already been obtained. Of course it needs a new timing chain, fuel pump, water pump and divider plate. But everything else is there.

Return to 1972 Lemans Page

Last updated January 28th, 2007