Gas Tank Investigation - 01/17/2015

Non functioning gauges are a source of frustration, especially the gas gauge in particular. I am never thrilled to not know how much gas is in the tank, and running out really hit home that I needed to solve why. So I went for it!

First things first, pull off the wheel to gain access. Gives me a chance to see the condition of the drum brake assembly. 12" finned brake drums. Obligatory spiders nests included at no charge.

Drum hardware in good shape. Not rusty or bound or any leaks. Plenty of dead spiders and brake dust though.

A car with massive drum brakes that never had the rivets grind? Say it ain't so!

I saw this on the frame underneath the gas tank. It is a serial number and a date of June 5th, 1973. Indicates when the frame was made?

Protective cover for the gas tank. Four screws to remove.

And we couldn't possibly have kept all the screws together, had to use a different one that is not only larger but is also metric!

I love it when the first sign of failure is completely obvious...

Tank is removed as a whole without too much effort since it's completely empty of gas.

Words fail me completely. Not only was the ground not hooked up and wrapped around the tubes like it isn't important, it isn't even connected to the tank anymore. Looks like someone chewed on it...

Sending unit is out. Fortunately it's not damaged.

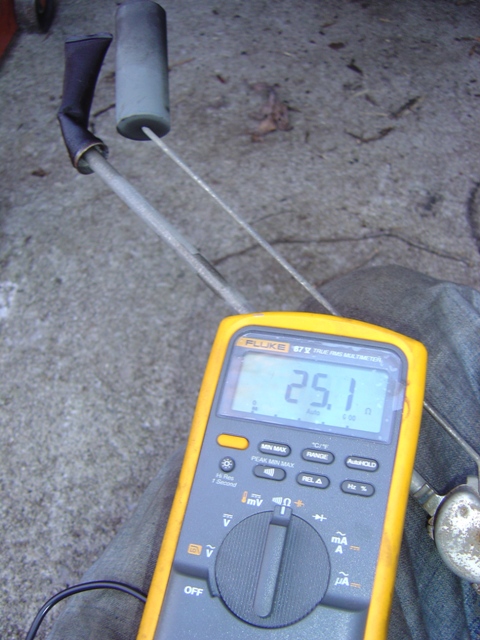

Testing empty reveals 25 ohms...

...and testing for full reveals 111 ohms. A 25 ohm offset, so at empty it will read a 1/3 of a tank left...

Fixed sending unit ground wire. Lots of wire brushing, splicing in new wire, and heavy duty soldering to the ground tab. Solder flowed pretty well after cleaning it up and getting it hot so the fix should hold. Heat shrink over the solder repairs as well - I don't like butt splices...

Always test our work before putting it back in the tank and re-assembling it all!

Hmm. 1/4 of a tank at empty... Not great.

More wire brushing and delicate cleaning of the wiring inside of the potentiometer wiper and braid gets it to be a little less than 1/8 of a tank at full empty. There is a 6.5 ohm offset. Not *ideal* but considerably better than before. Last time I did this a few tanks of gas and the cycling ended up cleaning things off and it worked better. Considering the sending unit isn't reproduced and finding a NOS one or good used is not exactly easy, this will work just fine for now.

Looking inside reveals it's actually pretty clean. Some tan plastic like material is covering roughly 1/3 of the tank. I presume it's some kind of kit that you mix together to seal the tank and keep it from rusting internally that is so popular. But apparently whoever did it didn't make enough or didn't let it slide all around the tank enough to get everything. Looks like the seller's claims of boiling out the tank were true at least. Too bad whoever did it was a moron who butchered the wiring.

Checking the view out shows no real rust, which is nice! Amusingly they repaired one broken wire (license plate lamp) but ignored the sending unit wiring which is very OBVIOUSLY broken.

Sending unit wire repaired. Solder and heat shrink.

Tank and sending unit are all back together and positioned for action. The rubber ring could stand to be replaced but I didn't have one.

Tank is fully installed. Went back together without issue. Ground hooked up, rubber lines that have been replaced in the not so distant past are put back on (factory clamps still in good shape), and straps all put back on. Not too bad of a job.

Well that wasn't too bad. Lots of eye rolling and head shaking today, why would someone screw something up this bad and then not fix it? It's pretty easy and having a working fuel gauge is definitely a quality of life thing I can't imagine people not wanting... Oh well, it's fixed now!

Return to 1973 Grand Safari

Last updated January 17th, 2015