The New Engine - Part 7 - 05/03/2009

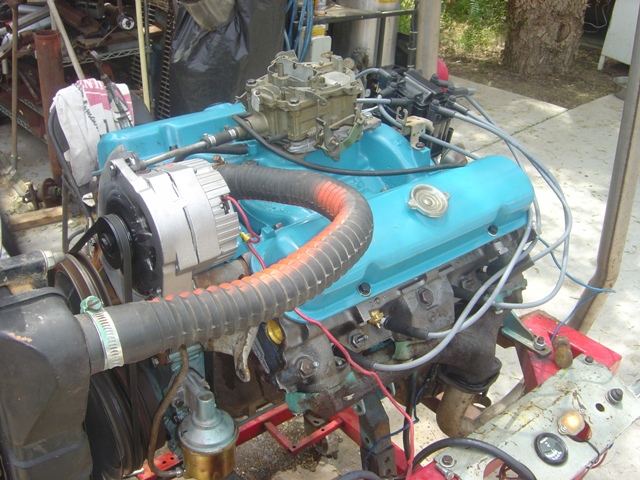

Fixed distributor, adjusted carburetor, food and rest should make this go much better than yesterday. Get the engine running and warmed up, get some oil changes in, adjust the valves, work the throttle back and forth to listen for funny noises, standard stuff.

Doing some adjustments to make it run smoothly.

Backing off the rocker studs to let the valves clack, then back to no clack, 1/2 turn after that.

Same for the other side. Steve took alot of burning oil right in the chest and ratchet, so the oiling system is very good on this engine.

Oil change! Even the thick 15W40 runs out like water. Filter was a little heavier than a normal filter change, but that's to be expected after breaking in a new engine. Absolutely nothing in the oil either. Some small particles in the filter, but no serious copper or anything like that. Having 60psi at 1200RPM or higher and 50psi at low idle even when fully warmed up is a sign of good clearances in the engine.

Getting more run-time in. Oil leaks and water leaks are in check now, no more smoke or water drips. Need to re-do the temperature sending unit with a little more teflon tape to stop a leak. The water pump bolts were a little loose once this was over and so were the intake bolts. But all is better now that they are tightened back down. I looked in the radiator and saw water flying through the tubes, so the new clearanced divider plate, cast impeller, and new tube o-rings are doing their job effectively. Since the engine never got above 190 during break-in, even with a thermostat, that's impressive.

Temperature in the radiator is 170 degrees with the clutch fan only. Not bad for made in China...

More videos!

Running 0:10

Running 0:10 - Valve adjustment. Steve got these almost dead on when the engine was on the stand.

Running 0:03 - Our electric fan keeps the clutch fan from engaging...

Running 0:20 - Even more valve adjustments.

Running 0:05 - More running. Probably over 45 minutes of run-time by now.

Next we rebuild a 1977 Pontiac 400 carb and dial it in on the stand. The distributor is done: 14° initial, 12° vacuum advance on manifold vacuum, 053 weights, a 363 center plate, and stock springs. Total advance is probably going to be around 36° which is what I was aiming for. Melling SPC-7 cam, 6X-4 heads for ~8.5:1 compression ratio. Should be a pretty nice running engine! Since the transmission is done, only need to paint the engine and drop it down in. The radiator for the car was with it, but it seems to have gone missing... would suck to have to replace it with a $200 new one! Although aluminum replacements do seem attractive...

Return to '75 Trans Am Page

Last updated May 3rd, 2009