AC Repair - Part 1 - 08/22/2015

I'm going to be honest here and call this "part 1" with an implied "hopefully no more than 2 parts as more than 5 would suck" tagged on the end. I'm learning AC work because shops that do this well are hard to find and expensive and shops that do this terribly are everywhere and don't cost much less than the shops that do it well. Gives me an incentive to learn to fix my own. I do have half a dozen cars and being in a place where the heat and humidity exist, the need to have working AC is very much one I hold near and dear to my heart. The truck had trouble with the AC. It was low and the high side Schrader valve was bubbling. I re-seated it a bunch of times a few weeks ago and the AC was ok, but not stellar. It would get to roughly 55F which at 95F sure is an improvement, but it could be better. I also noticed my recirculate feature was not working, which can help you verify if you're truly getting good cabin cooling or not.

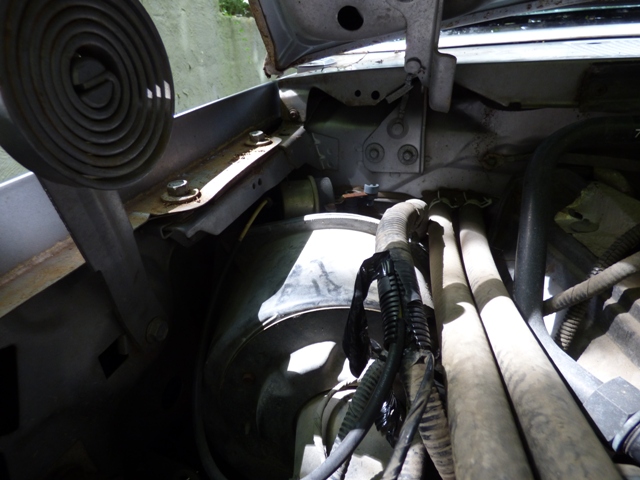

First things first. The recirculate diaphragm is over here outside on the evaporator box. This is a much better configuration than GM making it on the OTHER side of the firewall... It doesn't do anything.

The handy Mity-Vac earns its keep again: the diapragm and assembly are good, the vacuum hose to it is bad. I really hope it's just on the engine side...

You can't really see anything wrong here, but the plastic is definitely bad. Doesn't hold a vacuum. Very brittle and dry.

I had to cut back 6" of bad vacuum hose to get to good stuff. I reapplied the vinyl wrap to hide everything when done.

This is how we've been blowing for a few weeks. Not stellar but not horrible either. Need to fix it!

Got some seals!

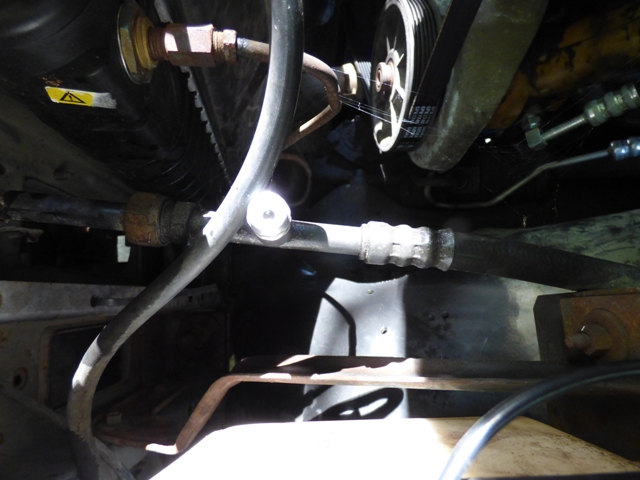

The high side port. It doesn't have the same "R134a standard" Schrader valve as the low side and all of the drawings indicate it should. This means one of two things: Ford's supplier was asleep at the wheel the day this was built or the original leaked at one time and an AC shop put on whatever was laying around to get the job done. I admire the can-do git-it-dun attitude, but it is frustrating when you're trying to source parts. There's some dye in this port after I had cleaned it up and injected dye last time so I know it's leaking a little here...

Oops. High side cap broke. Oh well. Luckily new ones are cheap.

Low side port has the proper Schrader valve. Some dye is here too but I don't know if it's from last time or not as I can't remember if I cleaned it... I definitely cleaned it now though!

I mixed up a nice bottle of Dawn dishwashing liquid and water to soap up everything to see if I have any obvious leaks. Condensor to evaporator fitting here can leak but wasn't.

Three fittings here on the receiver\drier assembly can leak, no evidence (bubbles) here either. Original Ford Motorcraft part...

Manifold fitting to condensor from compressor and receiver, some slight bubbles here I thought... Gave it a little turn and they aren't there now.

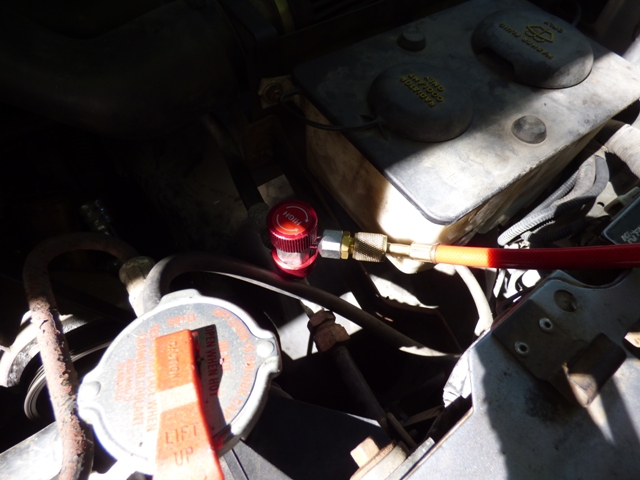

Hooking up the gauges. I like these, they have the shut-off valve built in, so you don't have to fight the pressurized system to hook them up and can easily prevent freon from escaping. And if you have ever had to take the test to be a licensed AC mechanic, you'll know the EPA requires you have these things (and know that cheap gauges don't come with them).

High side hookup has the same shut-off valve. These are idiot proof, both valves are different sizes and you can't interchange them.

Check the static pressure. It's 85F out and the truck hasn't run in 2 days, so it's nice and static-y. Fortunately both sides are equal so we know there's no blockage in the system, but the static pressure is around 72-75psi or so. This means there's freon in the system but it isn't liquid as the static liquid pressure is ~88psi, indicating a low charge condition. By the way, always keep the high pressure knob CLOSED on a charged system. Bad juju if you open it or worse, open both sides while it's running.

So we know we're low. Add some freon! I don't have an empty system nor do I have a scale, so I have to read the gauges and the temperature to verify "full" charge or as close to it as I can get. The lukewarm water keeps the freon from freezing in the can. Charge while the system is running.

The pressures build! This is where it gets interesting trying to determine full charge. There are charts that indicate what your high and low side pressures "should" be based on outside temperature and you should try to match them. Reality is always different naturally. Here I've got 35psi on the low side and almost 250psi on the high side. I was concerned about this, but then the clutch fan started ROARING and the pressure on the high side dropped down to about 200psi and the low side was around 35psi. Everything I've read indicates that your condensor design, engine speed, and fan flow through your condensor (heat removal) all have an effect on what pressures you'll see. I ended up adding 12oz of freon to the system and the low pressure side was 35psi and the high pressure settled down to around 190psi. The charts say these values are "low" for the ambient temperature of 85F outside, but considering how cold it got inside...

That's less than 40F, around 38F or so. You can't get an AC system to get colder than that as the evaporator will freeze - a fully charged properly functioning system will work about this well.

So, tightened one fitting and finished adding freon to the system to get it functioning better than I've ever had it. I'll replace the leaking Schrader fitting when the tools come in on Monday, but the AC is REALLY cold and functioning pretty well for now. If it continues to function beautifully, I'll probably be lazy and not fix it right away. I do have to do the '73 and the '67, so this is good practice.

Return to '95 F250 Page

Last updated August 22nd, 2015